Alpha Series

Alpha series is a system that

controls the movements of

Cartesian axes, which enables

the fulfilment of linear and

circular interpolation in the

work area of the robot.

Using programming software,

you can easily load sequences

of processes on the central unit

memory, which is independent

and can be subsequently

controlled not only from the

software and LCD panel, but

also via serial commands,

inputs and outputs and

CANOpen® commands.

Alpha is equipped with a

user-friendly programming

graphic interface and excellent

precision performances, speed

and acceleration.

Control Software

The PC software interface, which can be connected to the USB port of the

central unit, aids users in programming through the following actions:

Configuring the system

Number and dimensions of the axes, configuration of the ramps and maximum speeds, type of sensors installed etc.

Programming the process

The movement steps of the robot (point, line, arch, circumference, area) generate 3D movement sequences, both “point-to-point” and “continuous path”, which can detect inputs or activate outputs during their execution. Via the flow control steps (comment, branch, jump, calibration line, delay, input detection, output setting, sub-program execution), it is possible to implement cycles, sub-routines, portions of program perfectly similar to the programming language; the user is therefore able to fulfil various applications with maximum control of the system.

Setting the coordinates from files type

DXF(CAD), DXF(CAD), GDO(Gerber), XLS (Excel): this cuts right down on robot programming times, by exploiting the information that users already know from other systems. Functions such as copy/paste, drag and drop, multiple edit and the possibility to create sub-programs, help the user in rapidly controlling the final application and ensure maximum precision and repeatability in production contexts and de-structured environments and are always preserved thanks to specific parameters (anticipate output activation, calibration lines,...).

Diagnosing and testing the program in real time

Thanks to the 3D view of the paths and the “step by step” execution of each single step, it is possible to verify the positions and test the robot program to fine-tune and calibrate the final application.

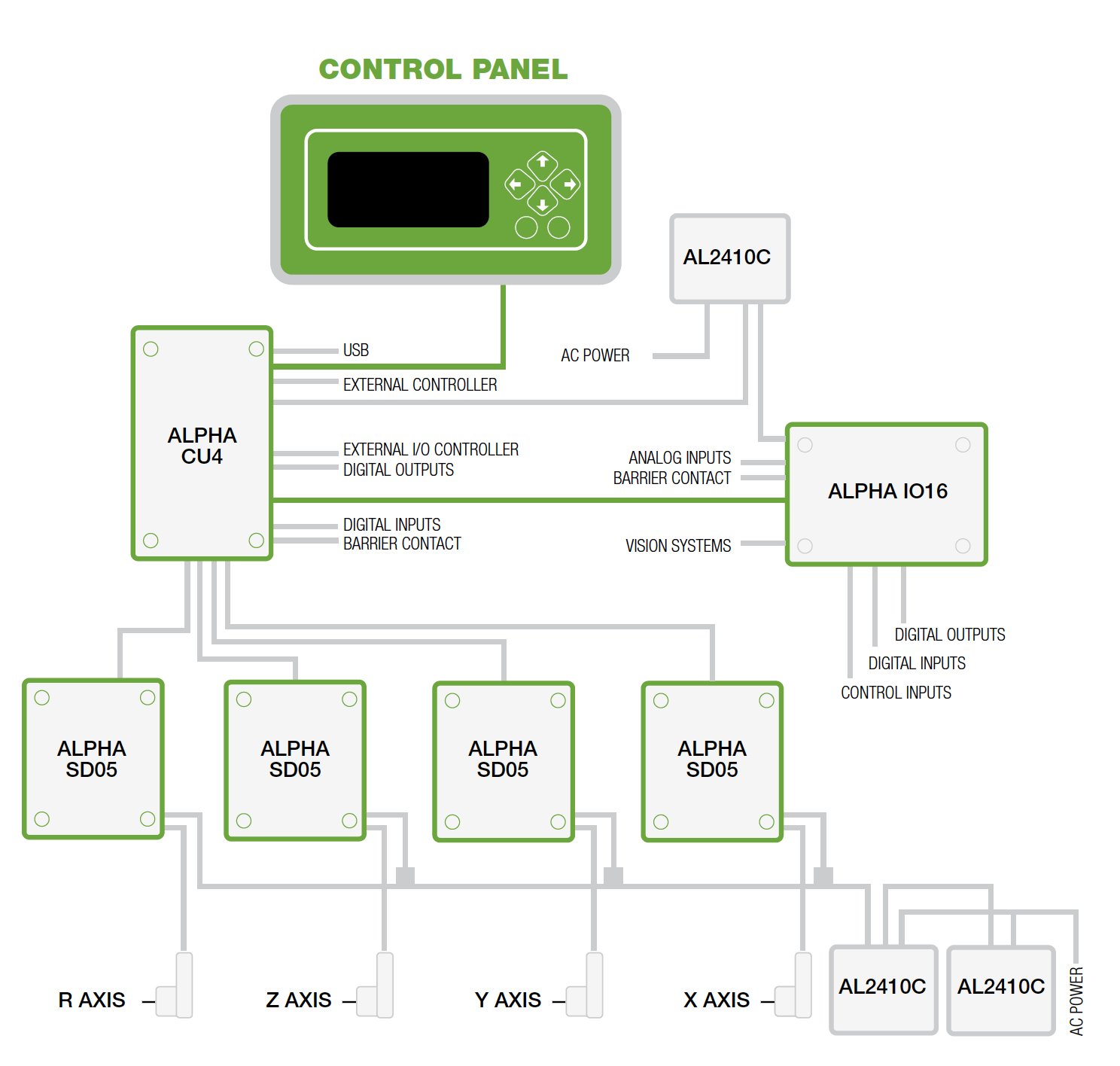

Hardware Parts

ALPHA CU4

ALPHA IO16

The digital input/output board ALPHA IO16 is used to expand the input and

output contacts. All the contacts are optoisolated and protected and can be

used in PNP or NPN configuration and two outputs have relays. The board

offers: 16 optoisolated “General purpose” inputs for connecting sensors,

external push buttons, PLC outputs etc..11 digital optoisolated control inputs.

16 “General purpose” outputs for connecting tools, indicators etc.(digital

optoisolated outputs / relay outputs). 7 status outputs. In addition, there is a

serial connector for feasible future utilities. The board is used to manage the

safety barrier.DRIVER SD05

ALPHA CP

Alpha Cp is the Control Panel for diagnosing and commanding ALPHA systems.

It is used to display the status of the robot and to manage the following menus

in real time: Select program / Robot controls menu / Inputs-Outputs Status /

Diagnosis / Select language / Adjust display. The rear-lit LCD has 6 buttons to

display and manage the menus (Standard on WRL300-WRa300-WRa500).